Useful Tips and Subtleties

Useful Tips and subtleties for proper installation of air suspension parts

As air suspension specialists, we at Aeropic strive to ensure that all installers are well-informed and confident when carrying out air suspension sistems. This article provides some valuable tips and tricks on possible obstacles you may encounter during installation.

Air Spring

When installing an air spring, always double check that the lower base is installed / clamped in place. Otherwise, it may break or the air spring may move out of place.

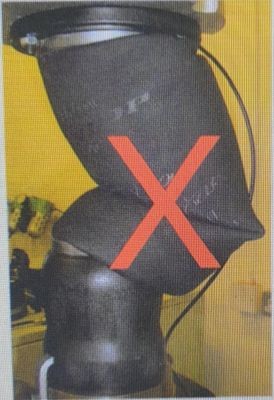

Make sure that the intake air pipe is correctly positioned and directed. Improper installation can lead to additional complications between the air spring and chassis components.

Under no circumstances stretch the cushion length by a millimeter before or during installation. Always inflate the air spring while the vehicle is on the ground but still held by the lift. Never release the vehicle with all its weight on an as yet uninflated air spring! Ignoring the above, the weight of the vehicle is unevenly distributed. Therefore, the air spring may bend during the inflation procedure.

The stress on it can be so great that it leads to the removal of the rubber sleeve from the crimping ring.

Keep in mind that after the final inflation of the air spring, the next 20-30 minutes are extremely risky for her. During this time, it is absolutely unacceptable to lift the hoist further so that the newly inflated air spring does not unfold / lengthen. This time is needed for her to be in the right position. During this time, the car must not be local at all and must remain at rest.

When changing the air spring, always make sure that you have checked the shock absorber thoroughly. Note that a damaged shock absorber could also be responsible for cushioning the air spring. When the damping force of the shock absorber is no longer sufficient, the air spring must absorb more shocks and more movement, which leads to repeated thermal overload. This shortens its life and can lead to cracking of rubber parts or breakage of the lower or upper base.

Fittings

When installing the air duct to an air spring or shock absorber, it is not necessary to tighten the fitting too much. The manufacturers recommend tightening the fitting to a maximum of 2Nm. When more and more torque is used, this can damage the screw thread, which will cause air to escape from the air spring. Even if there is a small leak, over time it can overload the compressor. Always check after installation with soap suds for air leaks and air bubbles.

After installing the shock absorbers with electrical cables, check that the connectors are positioned correctly. Improper installation or loose connectors can generate error codes.

Carefully tighten the upper shock absorber bolts to the body. In general, manufacturers do not recommend the use of pneumatic tools for this. Excessive tightening of the bolts can damage their threads or even break them.

Air suspension compressor

Burning or overloading the Air Suspension Compressor is often a follow-up damage, so it is crucial to check the air suspension system for air leaks. It is usually easy to tell if the compressor has been damaged due to burns / overloads because it smells burnt, the compressor labels have turned yellow due to the heat and often all non-metallic parts are also partially melted. If this is the case, you should not just replace it with a new air suspension compressor, but you must find the main reason for its overload. Otherwise, the new compressor will probably also be damaged in a short time.

When replacing the air suspension compressor, always replace the relay and check or replace the air filter. The compressor is switched on and off by a relay which is controlled by the electronic control unit (ECU). The relay can stick, which leads to continuous operation of the compressor. This will eventually lead to its overloading and burning. Fresh air enters the air suspension compressor and passes through an air filter. If the old compressor is damaged due to water and / or dirt inside, it is likely that the air filter has been dirty. If in this case only a new compressor is replaced, it will also work with existing water, moisture and debris.

_result.jpg)

After replacing the compressor, always check the condition of the inlets and all boiler hoses. The suction hose is rubber and can dry out and become porous, causing leakage and / or detachment from the compressor. In both situations, this causes water, moisture and dirt to enter the compressor, which will subsequently damage it. Always revise the integrity and permeability of the rubber hoses and replace with new air filters. Also check the reliability of the connection between the rubber hose and the compressor. Be sure to check the compressor wiring for broken or cracked wires. The compressor can vibrate during operation, which leads to wiring wear. The vibrations themselves increase over time, both due to the gradual wear of the compressor and due to the hardening of the rubber pads on its suspension. When replacing an air suspension compressor, it is also advisable to replace new spring pads.